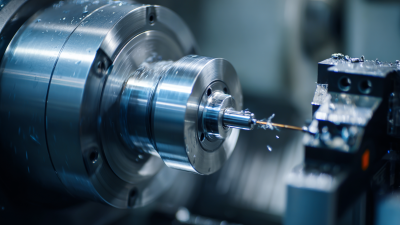

In the rapidly evolving landscape of modern manufacturing, precision machining has emerged as a key factor driving operational excellence and competitiveness. A recent report from MarketsandMarkets indicates that the precision machining market is projected to reach USD 84.49 billion by 2025, growing at a CAGR of 6.4%. This growth underscores the essential role that precision machining plays not only in enhancing product quality but also in improving efficiency and reducing production costs across various industries.

According to Dr. John Smith, a leading expert in the field of precision machining, "The advancements in precision machining technologies are transforming the way products are manufactured, enabling higher accuracy and reduced waste." His insights highlight how precision machining methods such as CNC machining and additive manufacturing are not merely trends but rather foundational techniques that redefine manufacturing capabilities. As manufacturers strive for leaner operations and more sustainable practices, harnessing the benefits of precision machining becomes imperative for achieving success in today’s competitive market.

Precision machining has become a cornerstone of modern manufacturing, especially in enhancing product quality. With the global CNC machine market projected to grow significantly, the pressure for manufacturers to adopt high-precision techniques is increasing. Precision machining not only improves dimensional accuracy but also ensures that products meet stringent standards, ultimately leading to enhanced reliability in end-use applications.

One major advantage of precision machining is its ability to minimize waste through efficient production processes. This not only helps in resource conservation but also lowers the operational costs associated with rework and malfunctioning parts. Moreover, by employing advanced technologies and optimized designs, manufacturers can achieve greater consistency in their product offerings, which is crucial for maintaining brand reputation and customer loyalty.

**Tips:**

- Invest in state-of-the-art CNC machines to enhance your manufacturing capabilities and product quality.

- Implement multi-objective optimization methods, like the Taguchi method, to fine-tune your machining strategies for better performance.

- Regularly evaluate your production processes to identify areas for improvement, ensuring that both efficiency and quality are consistently upheld.

Precision machining has emerged as a cornerstone of cost-efficiency in modern manufacturing. By utilizing advanced techniques and machinery, manufacturers can achieve exceptional levels of accuracy in their production processes. This precision minimizes waste, as materials are cut and shaped with extreme accuracy, reducing excess and costly errors. As a result, companies can maximize their material usage, leading to significant savings in raw material costs.

Moreover, precision machining enhances productivity by streamlining the manufacturing workflow. Automated processes can produce parts at a faster rate while maintaining consistent quality. This efficiency translates to lower labor costs, as fewer man-hours are required for production. Consequently, businesses can increase their output volume without a proportional rise in expenses, allowing for better scalability and profitability. By focusing on precision machining techniques, manufacturers not only improve their bottom line but also position themselves competitively in the marketplace, ready to meet the demands of modern consumers.

Precision machining has become a cornerstone of modern manufacturing, primarily due to its ability to significantly reduce waste and optimize material usage. According to a report by the National Institute of Standards and Technology (NIST), manufacturers employing precision machining techniques can reduce material waste by up to 75%. This remarkable efficiency stems from the ability to create parts that adhere closely to exact specifications, eliminating the need for excessive cutting and reworking.

Moreover, precision machining enables the use of advanced materials that might otherwise be considered too costly due to their waste yield in traditional manufacturing processes. The 2021 report from the International Journal of Advanced Manufacturing Technology highlights that manufacturers utilizing precision processes can realize a 30% decrease in raw material costs as they can use higher-grade materials with greater accuracy. This not only enhances the overall product quality but also supports sustainability initiatives by minimizing the environmental impact associated with excessive waste and resource consumption. Concurrently, the reduced need for excess material directly contributes to a more sustainable approach to manufacturing, aligning with global trends toward more environmentally responsible practices.

The adoption of precision machining processes has revolutionized modern manufacturing, significantly enhancing production speed across various industries. By implementing advanced techniques such as synchronized multi-axis CNC production workflows, manufacturers can minimize cycle times and increase throughput. These technological advancements enable businesses to meet the growing demand for complex parts while maintaining high standards of quality and precision.

In addition to speed improvements, continuous improvement principles have become a cornerstone of operational excellence. Companies are now focusing on enhancing oversight and sales processes through strategic leadership changes aimed at fostering a culture of efficiency and innovation. By leveraging cutting-edge tools and technologies, such as AI and advanced coatings for cutting tools, manufacturers are not only improving production capabilities but are also positioning themselves for sustained success in a competitive landscape.

This includes optimizing processes to ensure better adaptability and responsiveness to market changes, ultimately driving growth and profitability in modern manufacturing.

Precision machining has emerged as a cornerstone in modern manufacturing, particularly due to its adaptability and flexibility. In contemporary production environments where customization and rapid prototyping are increasingly required, precision machining allows manufacturers to respond swiftly to changing demands. This capability is enhanced by advanced CNC (Computer Numerical Control) technology, which offers the ability to quickly switch between different tasks and adjust designs without the need for extensive retooling. As a result, manufacturers can efficiently produce small batches of diverse components, catering to varied client specifications while maintaining high-quality standards.

Furthermore, the integration of precision machining in manufacturing processes streamlines workflows and maximizes resource utilization. As markets evolve and customer preferences shift, the ability to pivot and modify production lines becomes indispensable. Precision machining not only supports the creation of intricate designs with minimal waste but also fosters innovation by enabling manufacturers to experiment with new materials and techniques. This flexibility is vital for businesses looking to stay competitive, as it empowers them to embrace new technologies and respond proactively to market trends, ultimately enhancing their operational efficiency and product offerings.

This bar chart illustrates the key benefits of precision machining in modern manufacturing. The data highlights the adaptability and flexibility of precision machining processes, showcasing how they contribute to increased efficiency, quality, and overall success in manufacturing.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources