In today's global manufacturing landscape, efficient cutting machining solutions are essential for maintaining competitiveness and achieving operational excellence. According to a report by MarketsandMarkets, the cutting tools market is projected to grow from USD 24.92 billion in 2020 to USD 31.37 billion by 2025, reflecting a CAGR of 5.1%. As industries increasingly rely on precision engineering and automation, China has emerged as a leader in providing innovative cutting machining technologies that address common challenges such as tool wear, accuracy, and production efficiency.

However, as companies strive for seamless integration of these solutions, they often encounter issues related to material compatibility, machine calibration, and operator training. This blog will explore the most pressing problems within the cutting machining sector and highlight how China’s advanced solutions can pave the way for enhanced manufacturing success on a global scale.

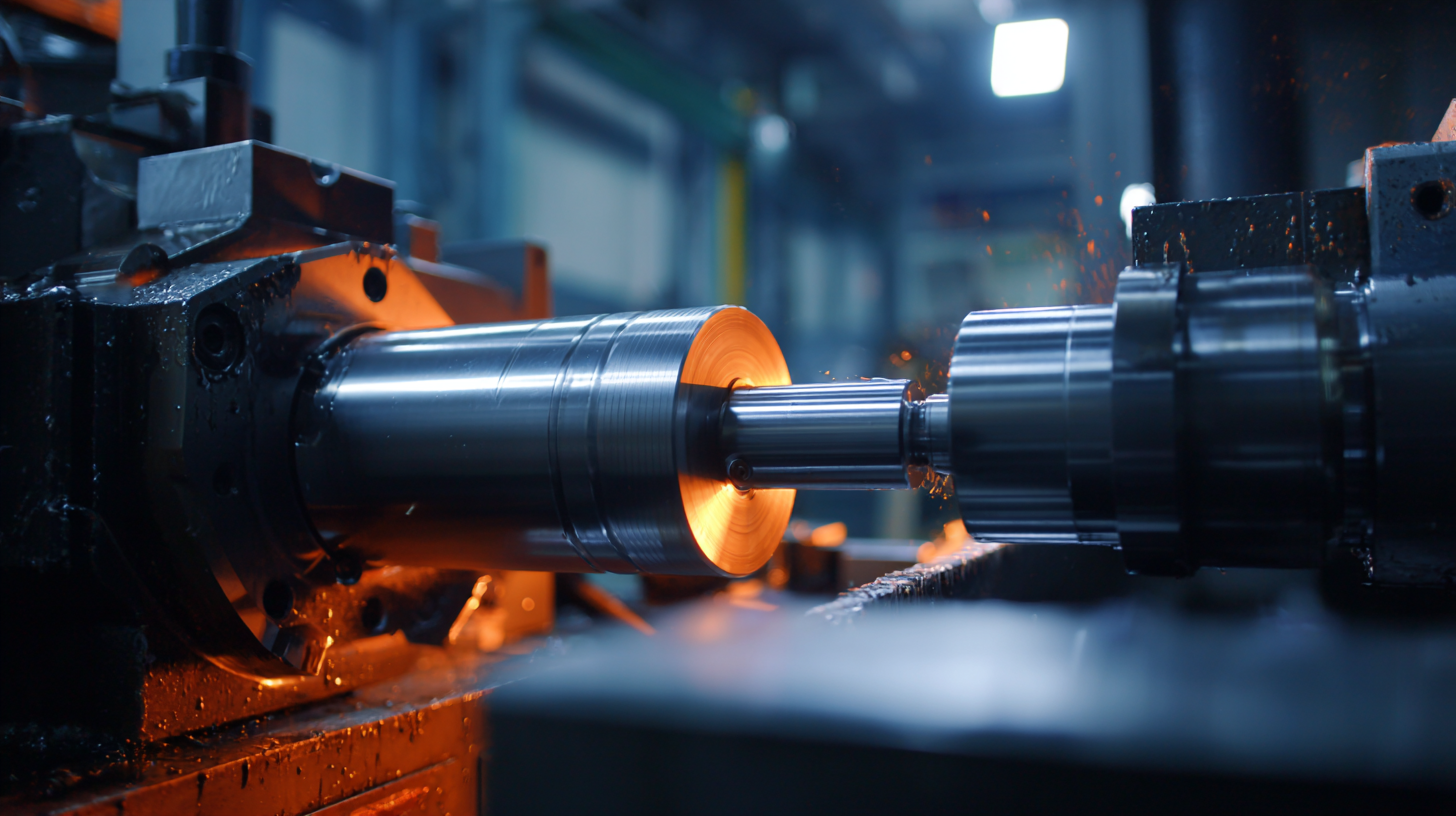

China's Precision Cutting Machining has made significant strides in recent years, positioning itself as a vital player in enhancing product quality across various industries. With the integration of advanced technologies and rigorous quality control processes, Chinese manufacturers are setting new benchmarks in precision cutting and machining. This evolution is driven by the demand for higher performance and efficiency, allowing companies to produce intricate designs with tight tolerances that meet international standards.

The latest advancements in CNC (Computer Numerical Control) technology and automation have revolutionized the machining landscape in China. Manufacturers are now equipped with sophisticated software and tools that enable faster production times and reduced error rates. Furthermore, the implementation of smart manufacturing practices is enhancing operational efficiency, allowing for real-time monitoring and optimization of processes. These innovations not only elevate the quality of finished products but also contribute to sustainable practices by minimizing waste and energy consumption in manufacturing.

As a result of these developments, Chinese precision cutting machining solutions are gaining recognition on a global scale. Companies looking to improve their manufacturing capabilities are increasingly turning to China for high-quality machining services that deliver both performance and reliability. The commitment to continual improvement and technology adoption ensures that China remains at the forefront of global manufacturing success.

| Category | Technology | Material Compatibility | Precision Level | Applications |

|---|---|---|---|---|

| CNC Machining | Computer Numerical Control | Metals, Plastics | ±0.01 mm | Automotive, Aerospace |

| Laser Cutting | Laser Technology | Plastics, Metals | ±0.05 mm | Signage, Industrial Components |

| Water Jet Cutting | High-Pressure Water Jet | Metals, Glass, Stone | ±0.2 mm | Architecture, Art |

| EDM Machining | Electrical Discharge Machining | Metals | ±0.005 mm | Mold & Die Making |

In the rapidly evolving manufacturing landscape, China's embrace of innovative technologies has positioned it as a global leader in cutting machining solutions. Automation, artificial intelligence, and advanced robotics are transforming traditional manufacturing processes, enhancing efficiency, and precision. The integration of these technologies not only streamlines production but also reduces waste and improves product quality, making it indispensable for manufacturers seeking to maintain a competitive edge.

Tip: When assessing cutting machining solutions, prioritize those that utilize the latest technological advancements. Investing in machinery that incorporates AI-driven analytics can provide insights into operational efficiencies, predict maintenance needs, and significantly reduce downtime.

The global demand for Chinese machining solutions is witnessing remarkable growth, as industries worldwide increasingly turn to China for cutting-edge manufacturing technologies. With the global machine learning market anticipated to surge from $35.32 billion in 2024 to $309.68 billion by 2030, Chinese manufacturers are well-positioned to leverage advancements in automation and data analytics. These technologies not only enhance machining precision but also enable manufacturers to optimize their operations, ultimately driving productivity and cost efficiency.

Moreover, the milling machine market is also set for significant expansion, projected to grow from USD 28.89 billion in 2024 to USD 52.69 billion by 2032. This growth suggests a robust appetite for innovative milling solutions, particularly those that enhance production capabilities in sectors like automotive, aerospace, and consumer goods. As global manufacturing continues to evolve, the integration of sophisticated machining solutions from China will be crucial for businesses aiming to remain competitive in an increasingly digital economy.

The collaboration between Chinese suppliers and international companies could uncover new opportunities that redefine manufacturing standards and practices across various industries.

In the rapidly evolving landscape of global manufacturing, China's cutting machining solutions are setting benchmarks for product quality and innovation. With a commitment to excellence, Chinese manufacturers are not only improving their production processes but are also aligning with international standards. This dedication is evidenced by their adoption of advanced technologies and rigorous quality control measures that ensure every product meets or exceeds global expectations.

Moreover, China's investment in training and skill development for its workforce plays a pivotal role in enhancing product quality. By prioritizing continuous improvement and innovation, Chinese companies are cultivating a culture that values precision and reliability. This strategic focus enables them to produce sophisticated components that cater to diverse industries, from aerospace to automotive, thereby reinforcing their position as leaders in the manufacturing sector. As they strive to meet global manufacturing standards, China's cutting machining solutions are poised to drive success in markets around the world.

China has emerged as a powerhouse in cutting machining solutions, significantly impacting global manufacturing industries. In recent years, reports indicate that the Chinese machining market has grown at an impressive CAGR of over 8% from 2016 to 2021, driven by advancements in technology and increased demand for precision components. Notable success stories illustrate how Chinese manufacturers have been able to optimize production processes, reduce lead times, and enhance product quality. For instance, a case involving a leading automotive supplier from Germany showcased how they paired with a Chinese machining firm, resulting in a 25% reduction in production costs while improving the component's performance metrics by 15%.

Another remarkable case study involves an American aerospace company that utilized China's cutting-edge machining solutions for its component fabrication. According to a report by CIMdata, companies incorporating Chinese machining technologies into their supply chain have reported up to a 30% increase in operational efficiency. This was achieved through the deployment of advanced CNC machines and robotics in China, aligning with Industry 4.0 practices. As these success stories highlight, partnering with Chinese manufacturers not only fosters innovation but also proves vital in maintaining a competitive edge in the rapidly evolving global market.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources