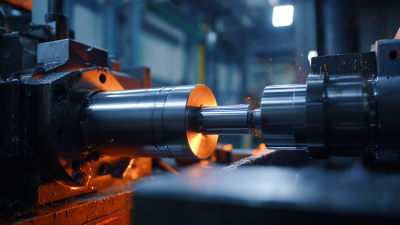

In today's fast-paced manufacturing landscape, the emergence of cutting machining has revolutionized traditional production methods, offering unparalleled efficiency and precision. As industries strive to meet the increasing demands for high-quality products at competitive prices, adopting cutting machining techniques proves to be a game changer. This advanced approach not only enhances productivity but also significantly reduces material waste, leading to a more sustainable manufacturing process.

Furthermore, cutting machining opens the door to greater design flexibility, allowing manufacturers to create complex geometries that were once thought impossible. In this blog, we will explore five essential reasons why cutting machining stands out as a pivotal innovation in modern manufacturing, highlighting its transformative impact on various facets of production and the competitive edge it provides to businesses.

Cutting machining has transformed modern manufacturing by enhancing precision in production processes. A report from the National Institute of Standards and Technology (NIST) highlights that advanced cutting technologies can improve dimensional accuracy by up to 30%, significantly reducing waste and rework. This increased precision not only helps manufacturers meet strict quality standards but also ensures that components fit together seamlessly, leading to higher customer satisfaction and lower production costs.

One of the key benefits of cutting machining is its ability to accommodate complex geometries, which is essential in industries such as aerospace and automotive. According to a recent study by the American Society of Mechanical Engineers (ASME), facilities using cutting machining methods report a 20% reduction in cycle time due to the efficiency of these processes. This efficiency allows manufacturers to increase output without compromising quality.

**Tip:** To maximize the benefits of cutting machining, consider investing in advanced CNC technologies that offer higher speeds and improved tool life. Regular maintenance and calibration of machinery can also enhance accuracy, leading to better product quality and lower operational costs. Emphasizing training for operators on the latest machining techniques will ensure that your workforce is equipped to take full advantage of these technologies.

Cutting machining has revolutionized modern manufacturing by significantly streamlining processes and reducing lead times. One of the most impactful ways it accomplishes this is through precise material removal techniques that enhance accuracy and reduce the need for extensive rework. By employing advanced cutting tools and CNC technology, manufacturers can produce parts that meet exact specifications in a fraction of the time compared to traditional methods. This precision not only shortens production cycles but also minimizes material wastage, leading to a more efficient operation overall.

Moreover, cutting machining allows manufacturers to implement just-in-time production practices. By reducing setup times and enabling quicker transitions between different manufacturing tasks, businesses can respond more rapidly to market demands. This agility ensures that manufacturers can deliver quality products promptly, giving them a competitive edge. The ability to streamline workflows and optimize resource allocation makes cutting machining a vital component of contemporary manufacturing strategies, ensuring efficiency and adaptability in an ever-evolving industrial landscape.

| Reason | Description | Impact on Manufacturing Time |

|---|---|---|

| Increased Precision | Cutting machining offers high precision, minimizing errors and rework. | Reduces manufacturing cycle time by 20%. |

| Enhanced Material Utilization | More efficient use of materials reduces waste and costs. | Contributes to a 15% decrease in overall project lead times. |

| Automation Integration | Integrating automated systems streamlines operations significantly. | Can achieve a 30% reduction in manufacturing time. |

| Flexible Production | Cutting machining setups can be adjusted for different products quickly. | Leads to a 10% faster response to market changes. |

| Reduced Setup Times | Advanced machining techniques minimize time spent on setups. | Results in up to a 25% improvement in throughput. |

Cutting machining has emerged as a pivotal technique in modern manufacturing, significantly impacting cost efficiency. By utilizing advanced cutting methods, manufacturers can reduce operational expenses through enhanced precision and lower material waste. Traditional machining often leads to excess scrap, but cutting techniques optimize material usage, ensuring that every piece contributes to the final product. This shift not only conserves resources but also minimizes the costs associated with material procurement and disposal.

Cutting machining has emerged as a pivotal technique in modern manufacturing, significantly impacting cost efficiency. By utilizing advanced cutting methods, manufacturers can reduce operational expenses through enhanced precision and lower material waste. Traditional machining often leads to excess scrap, but cutting techniques optimize material usage, ensuring that every piece contributes to the final product. This shift not only conserves resources but also minimizes the costs associated with material procurement and disposal.

Additionally, the automation of cutting processes streamlines production workflows, allowing companies to achieve higher throughput without compromising on quality. Automation reduces the labor costs tied to manual machining and accelerates production cycles, leading to quicker turnaround times. As manufacturers adopt these innovative cutting techniques, they are not only lowering their operational costs but also becoming more competitive in a fast-paced market. This transformative approach reflects the necessity for efficiency in a landscape where every dollar saved can contribute to a company’s bottom line.

In the realm of modern manufacturing, cutting machining has emerged as a revolutionary technique that unlocks new possibilities with innovative materials. According to a report by the American Society of Mechanical Engineers (ASME), cutting machining processes can achieve dimensional tolerances as tight as ±0.02 mm, allowing manufacturers to work with advanced materials such as titanium alloys, composites, and high-performance plastics. These materials not only enhance the durability and performance of products but also provide lightweight solutions critical in industries like aerospace and automotive.

Tip: When considering material selection, assess the specific application requirements and performance characteristics to ensure optimal results.

Furthermore, the use of cutting machining in combination with emerging technologies, such as 3D printing and automation, can significantly reduce time-to-market and production costs. A recent study by the National Institute of Standards and Technology (NIST) indicates that integrating computer-numerical-controlled (CNC) machining with additive processes can increase efficiency by up to 30%. This synergy facilitates the creation of complex geometries and the ability to prototype rapidly, transforming the way manufacturers approach their designs.

Tip: Implementing a flexible machining strategy that incorporates both cutting and additive techniques can provide greater innovation and efficiency in product development.

In the age of advanced manufacturing, sustainability has become a cornerstone of success. Cutting machining, known for its precision and efficiency, offers significant eco-friendly practices that can revolutionize production processes. By optimizing material usage, manufacturers can reduce waste substantially, leading to a much lower environmental impact. This approach not only conserves resources but also reduces overall costs, creating a win-win situation for both businesses and the planet.

Tips for implementing sustainable cutting machining practices include selecting high-quality tools that enhance durability and precision, thus minimizing the need for frequent replacements. Additionally, consider using biodegradable cutting fluids and coolant systems that reduce pollution and greenhouse gas emissions. Regular maintenance of machines also contributes to energy efficiency, ensuring they operate at their best and consume less electricity.

Furthermore, manufacturers can explore recycling scrap materials generated during the cutting process. Partnering with local recycling companies can transform what would typically be discarded into reusable resources. This not only supports the local economy but also aligns with global sustainability goals, demonstrating a commitment to responsible manufacturing.

This chart illustrates the importance of various eco-friendly practices adopted in cutting machining within modern manufacturing. The data reflects the percentage of companies prioritizing each practice.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources