In today's competitive manufacturing landscape, enhancing process efficiency and product quality is paramount for success. According to a recent report by the International Federation of Robotics, the global industrial robot market is projected to reach $70 billion by 2025, reflecting an increasing reliance on precision tools and automation in production environments. SGS precision tools play a vital role in this evolution, offering manufacturers the high accuracy and reliability required to meet industry standards. Implementing these advanced tools can lead to significant improvements in operational efficiency, reducing scrap rates by up to 30% and increasing production speeds.

In this blog, we will explore practical strategies for integrating SGS precision tools into your manufacturing processes, helping you to stay ahead in an ever-evolving market.

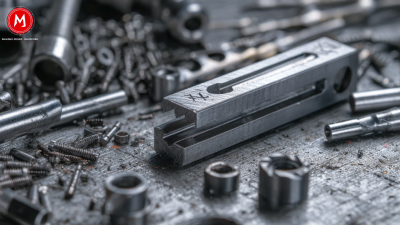

In today’s competitive manufacturing landscape, optimizing efficiency is paramount, and utilizing SGS Precision Tools can significantly enhance your production processes. These tools are renowned for their precision engineering, which facilitates higher cutting speeds and improved surface finishes. By replacing generic tools with SGS products, manufacturers can experience reduced cycle times and minimized material wastage, leading to enhanced productivity metrics.

Furthermore, SGS tools are designed with durability in mind, ensuring they withstand the rigors of high-volume manufacturing. This durability translates into less frequent tool changes, decreasing downtime and maintenance costs. Additionally, the consistency of SGS Precision Tools allows for repeatable results, enabling manufacturers to maintain strict tolerances and quality control throughout their production runs. The integration of these advanced tools into your manufacturing process not only improves overall efficiency but also elevates the final product quality, making it a worthwhile investment for any forward-thinking manufacturer.

In the competitive landscape of electronic manufacturing, enhancing production speed and quality is paramount. SGS precision tools stand out as pivotal assets in achieving these goals. The integration of these tools into manufacturing processes allows companies to streamline operations, minimize waste, and maximize output. By focusing on key metrics such as cycle time and defect rates, manufacturers can leverage SGS tools to establish a clear baseline for improvements.

One significant aspect of SGS tools is their ability to provide real-time data analytics, enabling manufacturers to make informed decisions quickly. This responsiveness not only accelerates production timelines but also ensures that quality control measures are consistently met. As electronic manufacturing continues to evolve, utilizing precision tools becomes essential in maintaining a competitive edge. With enhanced capabilities arising from SGS, manufacturers can adapt more swiftly to market demands and technological advancements, ensuring sustainable growth in an ever-changing industry.

| Metric | Before Implementation | After Implementation | Improvement (%) |

|---|---|---|---|

| Production Speed (units/hour) | 50 | 75 | 50% |

| Defect Rate (%) | 3.5 | 1.2 | 65.7% |

| Machine Utilization (%) | 70 | 85 | 21.4% |

| Operator Efficiency (%) | 78 | 90 | 15.4% |

| Cycle Time (minutes) | 10 | 7 | 30% |

When considering the implementation of SGS precision tools in your manufacturing process, analyzing the return on investment (ROI) is crucial. Cost-effectiveness plays a significant role in determining whether these advanced tools will lead to long-term savings and efficiency gains. By integrating SGS precision tools, manufacturers can achieve higher accuracy in their production processes, minimizing waste and reducing the costs associated with rework. This enhanced precision not only leads to improved product quality but also helps in maintaining tight tolerance levels that meet industry standards.

When considering the implementation of SGS precision tools in your manufacturing process, analyzing the return on investment (ROI) is crucial. Cost-effectiveness plays a significant role in determining whether these advanced tools will lead to long-term savings and efficiency gains. By integrating SGS precision tools, manufacturers can achieve higher accuracy in their production processes, minimizing waste and reducing the costs associated with rework. This enhanced precision not only leads to improved product quality but also helps in maintaining tight tolerance levels that meet industry standards.

Moreover, the initial investment in SGS tools should be weighed against potential operational savings. The durability and reliability of SGS precision tools often result in lower maintenance costs and decrease downtime, allowing manufacturers to optimize their production schedules. By evaluating the overall impact on productivity, including time savings and resource allocation, companies can better understand how SGS tools contribute to their bottom line. Investing in these tools may require upfront expenditure, but when considering the longevity and efficiency they bring, the ROI becomes evident, making it a wise choice for any forward-thinking manufacturer.

Precision tools play a crucial role in manufacturing by

reducing waste and errors, enhancing overall efficiency. The integration of advanced sensor systems in grinding

operations has been noted for its significant impact on tool condition monitoring. These systems utilize

technologies such as imaging and vibration analysis, enabling manufacturers to make informed adjustments that

minimize defects. As the metal cutting tools market

is projected to grow from $80.87 billion in

2023 to $113.04 billion by 2030, the demand for

precision tools that optimize performance and reduce waste is becoming increasingly critical.

Moreover, the advent of Industry 4.0 technologies,

including artificial intelligence, significantly contributes to sustainable manufacturing practices. For

instance, the implementation of digital twin technology aligns virtual and real machines, ensuring

precision that directly correlates with a reduction in manufacturing errors. Such innovations not only promise

to improve product quality but also facilitate the efficient use of resources, helping manufacturers to minimize

waste. As companies continue to adopt these technologies, the manufacturing landscape is set to evolve,

underscoring the importance of precision tools in

creating a more sustainable and efficient industry.

In the fast-evolving landscape of manufacturing, innovation is key to maintaining a competitive edge. SGS Precision Tools has been at the forefront of this revolution, integrating advanced technologies that streamline processes and enhance product quality. By incorporating state-of-the-art materials and smart design principles, SGS tools not only optimize performance but also reduce waste and operational costs. These innovations reflect a commitment to sustainability, ensuring that manufacturers can meet the growing demand for eco-friendly solutions without compromising efficiency.

In the fast-evolving landscape of manufacturing, innovation is key to maintaining a competitive edge. SGS Precision Tools has been at the forefront of this revolution, integrating advanced technologies that streamline processes and enhance product quality. By incorporating state-of-the-art materials and smart design principles, SGS tools not only optimize performance but also reduce waste and operational costs. These innovations reflect a commitment to sustainability, ensuring that manufacturers can meet the growing demand for eco-friendly solutions without compromising efficiency.

The future of manufacturing will heavily rely on the capabilities of precision tools that leverage robotics and artificial intelligence. SGS is pioneering the integration of these technologies, allowing for faster production cycles and higher levels of automation. With features such as adaptive cutting technologies and real-time data analytics, manufacturers can achieve unprecedented levels of precision and predict maintenance needs, ultimately leading to significant improvements in profitability and reliability. As industries continue to embrace these innovative tools, SGS is set to play a crucial role in shaping the future of manufacturing efficiency and innovation.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources