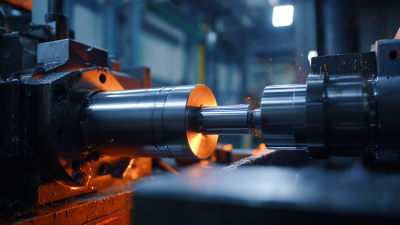

In the ever-evolving landscape of manufacturing, the quest for precision and efficiency has driven global buyers to explore innovative machining tools that cater to diverse needs. This blog will delve into a meticulously curated checklist of alternatives available in the market, providing insights into the latest advancements and technologies in machining tools. From traditional approaches to cutting-edge solutions, we will examine how these tools not only enhance productivity but also enable businesses to adapt to changing demands and foster innovation. As industries strive for sustainability and cost-effectiveness, understanding the spectrum of machining tools available can empower decision-makers to make informed choices that align with their operational goals. Join us on this exploration of innovative options that can elevate your manufacturing processes and meet the unique challenges of today’s competitive environment.

In today’s fast-paced manufacturing landscape, innovative machining tools are at the forefront of transforming industries, providing cutting-edge solutions that enhance efficiency and precision. As global buyers seek to stay competitive, the adoption of advanced technologies such as computer numerical control (CNC) machines, additive manufacturing, and automation systems is becoming increasingly essential. These innovative tools not only streamline production processes but also reduce operational costs while maintaining high-quality standards.

Furthermore, the integration of smart technology into machining tools, such as IoT connectivity and artificial intelligence, allows for real-time monitoring and predictive maintenance. This capability enables manufacturers to identify potential issues before they escalate, minimizing downtime and optimizing productivity. As industries evolve, the demand for versatile and adaptive tooling solutions continues to rise, leading to an unprecedented opportunity for global suppliers to deliver customized innovations that meet the specific needs of various sectors. By leveraging these advanced machining tools, manufacturers are empowered to push the boundaries of what’s possible, ultimately driving progress across the globe.

In the ever-evolving landscape of machining technology, key innovations are transforming efficiency and precision for global buyers. Advanced machining tools, such as high-speed machining centers and multi-axis CNC machines, offer unprecedented capabilities that streamline production processes. These technologies enable manufacturers to produce complex geometries with remarkable accuracy, significantly reducing lead times and minimizing material waste. Additionally, the integration of intelligent software solutions enhances productivity by optimizing machining parameters in real-time, allowing operators to achieve higher output rates without sacrificing quality.

Moreover, the rise of smart machining technologies, driven by the Internet of Things (IoT), is revolutionizing the manufacturing sector. Intelligent tools equipped with sensors and connectivity features provide invaluable data insights, facilitating predictive maintenance and enhancing overall operational efficiency. As a result, companies can proactively address issues, reduce downtime, and make data-driven decisions that propel their competitiveness on a global scale. The ongoing advancements in innovative machining tools are not only reshaping the industry but also expanding the horizons for manufacturers to meet the diverse needs of international markets.

The global machining equipment market is witnessing a significant shift as diverse alternatives gain traction among buyers. An analysis of current trends reveals that innovative machining tools not only enhance productivity but also cater to the evolving needs of global manufacturers. As of 2024, the machine learning market was valued at approximately $35.32 billion, with expectations of rapid growth—projected to reach $309.68 billion by 2030. This surge reflects the increasing integration of machine learning and artificial intelligence (AI) in a variety of industries, revolutionizing the landscape of machining equipment.

Moreover, the AI agents market is another area of robust expansion, estimated at $5.40 billion in 2024 and projected to soar to $50.31 billion by 2030, with a staggering compound annual growth rate (CAGR) of 45.8%. As companies seek to leverage these technologies, the development of innovative machining tools that incorporate AI and machine learning capabilities has become vital. This evolution not only promises operational efficiencies but also enables businesses to stay competitive in a rapidly changing market. The focus on diverse machining equipment choices aligns with the broader trend of tech adoption, driven by the need for improved supply chain management and enhanced productivity across various sectors.

| Machining Tool Type | Market Growth (%) 2023 | Key Materials | Application Industries | Region Leading Demand |

|---|---|---|---|---|

| CNC Machine Tools | 5.2% | Aluminum, Steel | Aerospace, Automotive | North America |

| Laser Cutting Machines | 7.8% | Carbon Steel, Stainless Steel | Manufacturing, Electronics | Asia Pacific |

| 3D Printers | 9.5% | Plastics, Composites | Healthcare, Aerospace | Europe |

| Waterjet Cutting Machines | 6.1% | Glass, Ceramics | Construction, Shipping | Middle East |

| Electrical Discharge Machines (EDM) | 4.9% | Titanium, Tungsten | Tool & Die, Aerospace | North America |

In today’s manufacturing landscape, sustainability is more pertinent than ever. Eco-friendly machining tools not only reduce environmental impact but also appeal to a growing market of conscious buyers. Companies are increasingly seeking tools made from recyclable materials and those designed to minimize waste during the machining process. Adopting these sustainable practices can lead to a more efficient production line while helping manufacturers align with global sustainability goals.

Tip: When sourcing eco-friendly tools, look for certifications or labels that indicate environmentally friendly practices. This can help in distinguishing genuine sustainable products from those making misleading claims.

Furthermore, utilizing innovative machining tools can enhance both the performance and lifespan of equipment, resulting in less frequent replacements and reducing overall waste. Transitioning to tools that use advanced technologies, such as digital monitoring and precision machining, can also lead to significant energy savings, which is a win-win situation for both the environment and the bottom line.

Tip: Consider involving your entire team in sustainability initiatives. Training on the benefits of eco-friendly tools and practices can promote a culture of responsibility and encourage innovative ideas for further efficiency improvements.

When selecting machining tools for global operations, several essential considerations come into play to ensure efficiency and success. According to a recent industry report from Grand View Research, the global machining tools market is expected to reach $105.15 billion by 2025, driven by demand for precision manufacturing across sectors. In this competitive landscape, understanding local regulations, material compatibility, and technological advancements is crucial for sourcing the right tools.

Tip: Ensure to conduct thorough research on local machining standards and regulations in the regions where you intend to operate. This will help avoid costly compliance issues and ensure smooth integration of your tools into existing workflows.

Moreover, considering the adaptability of machining tools is vital. A study by Mordor Intelligence indicates that multi-functional tools are gaining popularity, as they allow manufacturers to streamline processes and minimize downtime. The shift towards automation and Industry 4.0 demands that buyers invest in innovative tools that can integrate with smart technology for improved operational efficiency.

Tip: Look for suppliers that offer customizable solutions and after-sales support. Such partnerships can enhance your ability to scale operations while maintaining high-quality standards across various markets.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources