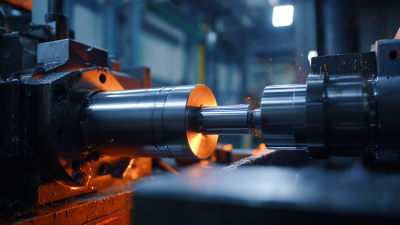

In the ever-evolving landscape of manufacturing, cutting machining has emerged as a critical technique for producing precision parts that meet the stringent demands of various industries. According to a report by Grand View Research, the global machine tools market, which includes cutting machining processes, is projected to reach USD 151.88 billion by 2025, expanding at a CAGR of 5.4%. This growth is driven by the increasing need for high accuracy in component fabrication across sectors such as Aerospace, Automotive, and Medical Devices. Mastering cutting machining techniques not only enhances production efficiency but also significantly improves the quality and precision of the final products. As manufacturers strive to adopt advanced methodologies and technologies, understanding the nuances of cutting machining becomes essential for those looking to stay competitive in this dynamic field.

In the realm of precision manufacturing, understanding cutting machining techniques is crucial for developing high-quality components. Key concepts such as the types of cutting processes—turning, milling, and grinding—play a significant role in ensuring accuracy and efficiency. For instance, turning operations can achieve tolerances as tight as ±0.01 mm, which is vital in industries where precision is non-negotiable. Moreover, advancements in tools and materials have substantially enhanced the performance of cutting processes, allowing manufacturers to achieve intricate designs that were previously unattainable.

With China rapidly becoming a leading innovator in advanced manufacturing technologies, the adoption of novel cutting techniques is essential for staying competitive. Recent studies indicate that employing digital twin technologies in machining can result in a 20-30% increase in efficiency by optimizing operational workflows and reducing downtime. In addition, the integration of data engineering trends, such as real-time monitoring of machining processes, is transforming how precision parts are produced. This data-driven approach not only enhances production capabilities but also allows for better resource management, underlining the importance of a comprehensive understanding of cutting machining techniques in today’s fast-evolving manufacturing landscape.

Material selection plays a pivotal role in cutting machining, significantly influencing both the precision of the finished parts and the longevity of the cutting tools. Different materials exhibit distinct properties, such as hardness, ductility, and thermal conductivity, which directly affect the machining process. For instance, harder materials may require tougher cutting tools that can withstand higher levels of wear and heat without losing their cutting edge. This consideration ensures that precision is maintained throughout the machining operation, reducing the likelihood of dimensional inaccuracies.

Moreover, the choice of material also impacts the overall efficiency of the machining process. Materials that are difficult to cut can lead to increased tool wear and downtime, necessitating more frequent tool changes. This not only escalates production costs but can also affect lead times. On the other hand, selecting the right material can enhance tool life and reduce the frequency of tool replacements, ultimately leading to more cost-effective and precise machining outcomes. Therefore, understanding the interplay between material characteristics and machining techniques is essential for achieving optimal results in precision manufacturing.

| Material Type | Hardness (HRc) | Cutting Speed (m/min) | Tool Material | Tool Life (mins) | Surface Finish (Ra μm) |

|---|---|---|---|---|---|

| Steel Alloy | 40 | 120 | Carbide | 50 | 0.8 |

| Aluminum | 15 | 300 | High-Speed Steel | 120 | 0.5 |

| Titanium Alloy | 35 | 50 | Ceramic | 30 | 1.0 |

| Brass | 8 | 200 | Tungsten Carbide | 80 | 0.6 |

| Plastic | N/A | 250 | High-Speed Steel | 150 | 0.4 |

Optimizing cutting parameters such as speed, feed rate, and depth of cut is crucial for enhancing the efficiency of machining processes, particularly when working with precision parts. Using a two-flute end mill cutter geometry, especially one that is centre cutting, allows for effective material removal while maintaining the integrity of the workpiece. The selection of appropriate spindle speeds can significantly impact tool life, especially under consistent feed rates. Studies have shown that varying the spindle speed while keeping the feed rate constant can lead to better performance and longevity of cutting tools.

Moreover, an investigation into the effects of cutting speed, feed rate, and depth of cut on surface roughness has highlighted their critical roles in CNC milling applications. For instance, in machining aluminum alloys like 6061, optimizing these parameters can greatly enhance surface quality and minimize defects. Advanced methodologies, such as coupling Taguchi experimental designs with AI models, provide a systematic approach to process optimization. This not only increases productivity but also reduces costs associated with manufacturing, making it essential for industries focused on precision component production.

In the world of precision parts manufacturing, the advancements in cutting machining technologies have become pivotal. According to a report by Grand View Research, the global CNC machining market alone is expected to reach $100 billion by 2025, driven by the growing demand for precision engineering in industries like aerospace, automotive, and medical devices. This highlights the urgent need for manufacturers to stay current with the latest tools and processes, as innovations in cutting machining are reshaping the landscape of production efficiency and product quality.

Advanced tools, such as multi-axis CNC machines and high-speed cutting technology, are redefining what's possible in manufacturing precision parts. The implementation of these technologies has shown to decrease production times by up to 30%, allowing for rapid prototyping and shorter time-to-market. Furthermore, reports indicate that integrating smart machining processes enhances accuracy and precision, minimizing material waste by as much as 20%. As the industry evolves, leveraging these cutting-edge innovations will be crucial for manufacturers aiming to sharpen their competitive edge in a rapidly changing marketplace.

Advanced tools, such as multi-axis CNC machines and high-speed cutting technology, are redefining what's possible in manufacturing precision parts. The implementation of these technologies has shown to decrease production times by up to 30%, allowing for rapid prototyping and shorter time-to-market. Furthermore, reports indicate that integrating smart machining processes enhances accuracy and precision, minimizing material waste by as much as 20%. As the industry evolves, leveraging these cutting-edge innovations will be crucial for manufacturers aiming to sharpen their competitive edge in a rapidly changing marketplace.

Achieving optimal quality control in cutting machining is crucial for producing precision parts that meet stringent specifications. The first step in ensuring tighter tolerances is meticulous measurement and monitoring during the machining process. Employing advanced measurement tools, such as coordinate measuring machines (CMMs) and laser scanners, can enhance accuracy and help identify deviations from desired dimensions in real time. Regular calibration of these measurement instruments further ensures that they provide reliable data, enabling operators to make necessary adjustments promptly.

In addition to precise measurements, maintaining a controlled environment plays a significant role in quality assurance. Factors such as temperature, humidity, and cleanliness can affect machining outcomes, leading to variations in surface finishes and tolerances. Implementing best practices like regular equipment maintenance and adhering to a strict cleaning protocol helps minimize the risk of contamination and wear. Incorporating rigorous inspection processes and continuous feedback loops into production can further bolster quality control, ultimately leading to improved consistency and durability of the machined parts.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources