In the world of automotive repair and maintenance, the significance of mastering mechanic tools cannot be overstated. According to a recent report by MarketsandMarkets, the global mechanic tools market is projected to reach USD 12.9 billion by 2025, driven by the rising demand for automotive service centers and the increase in vehicle production. As vehicle technology evolves, so does the complexity of repairs, necessitating a comprehensive understanding of essential mechanic tools that cater to both novice and professional mechanics alike. This guide aims to empower global buyers with the knowledge they need to select the right equipment, ensuring efficiency and effectiveness in their repair tasks. With the right tools in hand, mechanics can not only enhance their productivity but also contribute to the safety and longevity of the vehicles they service.

When it comes to equipping your workshop with essential mechanic tools, there are a few key items that every global buyer should prioritize. First on the list is a high-quality set of wrenches. A reliable wrench set, including both standard and metric sizes, is vital for tackling a variety of tasks, from simple repairs to more complex mechanical projects. Look for sets made from durable materials like chrome vanadium to ensure longevity and optimal performance. Additionally, ratcheting wrenches can offer efficiency, allowing for quicker adjustments without having to reposition the tool.

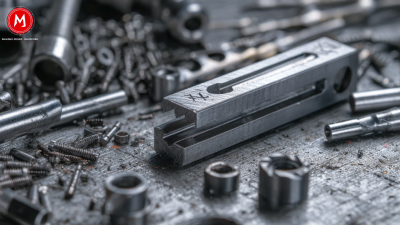

Another essential tool that should not be overlooked is the socket set. A comprehensive socket set offers versatility and ease for any mechanic, capable of handling different fasteners with ease. Investing in a set that includes both deep and shallow sockets, along with a sturdy ratchet, will provide the flexibility needed to navigate tight spaces and challenging angles. Furthermore, for precision work, torque wrenches are crucial to ensure that bolts are tightened to the manufacturer’s specifications, preventing damage to both parts and equipment. Together, these tools form the backbone of any well-equipped mechanical workspace.

When it comes to a mechanic's toolbox, having the right hand tools is essential for tackling a wide range of tasks with efficiency and precision. Among the myriad of tools available, there are five must-haves that stand out for their versatility and reliability. First and foremost is the trusty combination wrench. Its design allows for both tight and loose fastening, accommodating various nut and bolt sizes. With a combination wrench, mechanics can navigate tight spaces and secure connections seamlessly.

Another essential tool is the adjustable wrench, which offers flexibility by fitting different sizes of fasteners. This adaptability is invaluable when dealing with multiple projects or unfamiliar hardware specifications. Next on the list is a high-quality screwdriver set, encompassing various types and sizes to cater to different screws. Whether it’s Phillips or flathead, having the right screwdriver on hand ensures that mechanics can work on everything from vehicle interiors to small engine repairs with ease.

Lastly, a reliable pair of pliers and a torque wrench complete the toolbox essentials. Pliers provide the grip and leverage needed for various tasks, while a torque wrench guarantees that bolts are tightened to the correct specifications, preventing damage and ensuring safety. Together, these essential tools empower mechanics to perform repairs efficiently and effectively, making them indispensable for anyone in the trade.

As the automotive landscape rapidly evolves, having the right tools is increasingly vital for both professionals and DIY enthusiasts. With the rise of electric vehicles, traditional mechanics are embracing new technologies and techniques, making it essential to equip your garage with the latest power tools. From cordless impact wrenches that streamline tire changes to precision spark plug removal tools, these innovations can significantly enhance efficiency and effectiveness in automotive work.

With consumers purchasing more electric vehicles than ever before, investing in versatile tools is critical. Power tools that cater to the unique needs of modern vehicles—such as software-defined vehicles requiring specialized maintenance—are not just a trend but a necessity. By utilizing the right equipment, not only can you save on costly professional services, but you can also keep your vehicle in top shape, ensuring that it performs optimally in today’s tech-driven environment. This shift towards electrification and smarter car technologies means that staying up-to-date with essential mechanic equipment is more important than ever.

When selecting quality mechanic tools in today’s global market, there are several key factors to consider. The rapid growth in tool markets, notably the projected expansion of the global metal cutting tools market from $86.24 billion in 2025 to $141.65 billion by 2032, illustrates the importance of making informed choices. A compound annual growth rate of 7.3% highlights growing demand, necessitating buyers to prioritize durability, precision, and innovation in their equipment.

Additionally, the CNC machinery market is also on a significant upward trajectory, anticipated to soar from $101.22 billion in 2025 to $195.59 billion by 2032, with a remarkable CAGR of 9.9%. This trend emphasizes the need for buyers to select tools that not only meet current standards but also support future advancements. Consider factors such as supplier reputation, tool material, and technological integration when making your choice. With the right tools, mechanics can enhance efficiency and productivity in their work, ultimately leading to greater success in a competitive marketplace.

When it comes to selecting mechanic tools, understanding tool materials is crucial for durability and performance. Six key factors should guide global buyers in their decision-making process. First, one must consider the hardness of the material, typically measured on the Rockwell scale. Harder materials, like high-carbon steel, can withstand heavier use without deforming. According to a report by the International Tool Association, tools made from premium steels exhibit a 30% longer lifespan compared to those crafted from lower-grade metals.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources